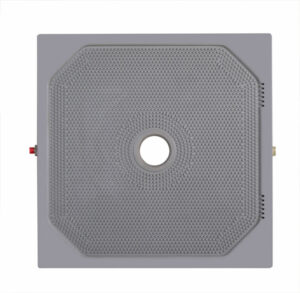

Model 2500 High Pressure Chamber Filter Plate

| Place of Origin: | Shandong, China |

|---|---|

| Brand Name: | ジンジン |

| Warranty: | 12 months |

Quick Details

Advanced Filter Plate Technology

We make our filter plates from high-quality polypropylene (PP) material using a precise molding process. The filtration surface has special channels designed to keep things running smoothly and prevent any blockages.

The JINGJIN plates are made of a mix of TPE elastomer, fiberglass, and polypropylene. This blend gives our plates great flexibility, toughness, and rigidity. After we do CNC machining, we keep the flatness of our filter plates below 25µm. This makes sure they seal well during pressing and stops any leaks when feeding.

All the specs of our plates meet not just the China JB/T4333.3-2005 standard but also the Germany DIN7129 standard. So, they work just fine with products from Europe and America.

Key Advantages:

Enhanced Filtration Speed

Superior Durability

High Feeding Pressure

Robust Performance

Efficient Filtration Cycle

Additional Benefits:

- Precision Engineering: The use of CNC machining ensures that our filter plates have a high degree of flatness, which is crucial for maintaining airtight seals and preventing leaks.

- Global Standards Compliance: By adhering to both Chinese and German standards, our filter plates are designed to meet the stringent requirements of international markets.

- Versatile Applications: The advanced material composition and design make our filter plates suitable for a wide range of industrial applications, from chemical processing to wastewater treatment.

Packaging & Delivery

Packaging Details: Plastic film winding, supported by the pallet

Port of Departure: Tianjin or as your request

Lead Time: According to the order quantity

Membrane Plate

- Outstanding Filtration Performance: Membrane plates provide exceptional filtration results and offer numerous benefits.

- Adjustable Solid Content: The solid content can be precisely controlled by adjusting the squeezing pressure.

- Enhanced Cake Quality: Performing a secondary squeeze after the initial filtration significantly increases the solid content of the cake.

- Efficient Pressure Management: Membrane plates operate under a “low pressure for filtration, higher pressure for squeezing” regime, which extends the lifespan of the plates and reduces energy consumption.

- Improved Washing Efficiency: These plates enhance the washing effect, shorten washing time, save washing liquid, and improve the quality of the final product.

Recessed Plate

- Variety of Specifications and Shapes: Jingjin has developed a wide range of filtration plates with various specifications and shapes to meet diverse needs.

- Material Versatility: Our plates are available in materials such as cast iron, steel Q235, cast steel, stainless steel, cast copper, aluminum alloy, polypropylene (PP), TPE elastomer, EPDM, NBR, and more.

- High Feeding Pressure: The maximum feeding pressure for our recessed plates is 3 MPa.

- Key Features: These plates offer high temperature and pressure resistance, excellent sealing and cake washing capabilities, anti-corrosion properties, short filtration periods, and lower cake moisture content.

What are the main features of the 2500 high-pressure chamber filter plate?

Material and Design

Material Advantages

Compliance with Standards

Performance Improvement

High Pressure Resistance

Foreign Customer

![]()

Packaging & Shipping

![]()

私達のプロダクトに興味があったら、私達に連絡しなさい!